Search: Site This Page

(405) 360-1552

| Ecovac Services / Projects / Treatability Studies / |

Coal Tar Treatability Study

IN-SITU COAL TAR REMEDIATION TREATABILITY TESTING

The purpose of this treatability test was to simulate in-situ remediation of highly viscous coal tar (Protar 2000) and to compare various remedial scenarios to determine the most effective and economical approach for in-situ coal tar remediation. Protar 2000 is a refined coal tar produced from high temperature coke oven tars. It is dark dense non-aqueous liquid (DNAPL) whose specific gravity is approximately 1.20 and viscosity is 2,500 centipoises (c.p.).

A fine grain sand derived from a fluvial/alluvial derived site was used during the treatability study. The sand samples were spiked with Protar 2000 to at least 20% NAPL residual saturation level (at least 20% of effective porosity was saturated with the NAPL). Ten different remedial approaches were simulated in the column tests, consisting of various formulations of surfactants and biosolvents combined with dual-phase/multi-phase extraction SURFAC® and SOLV-IT®.

Treatbility Testing Results Summary

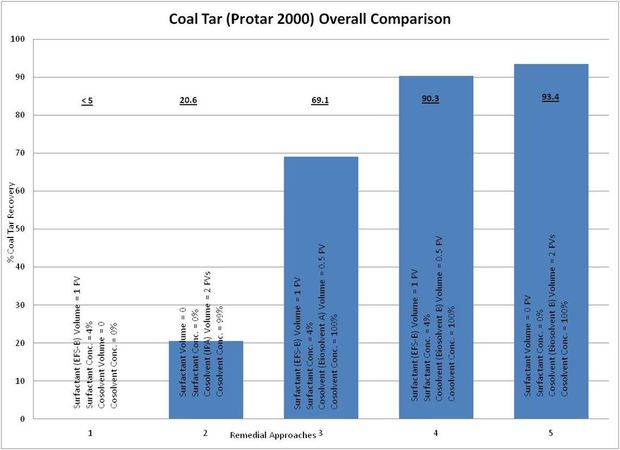

TPH reduction in the column tests ranged from < 5.0% to 94.1%, inclusive of three approaches that exceeded 90% TPH reduction. These three column test results are further described below with graphical representation.

1. SURFAC®/SOLV-IT® using half (0.5) pore volume of 100% commercially available Biosolvent #2 followed by one (1.0) pore volume of 4.0% EFSTM

a. TPH recovery percent = 90.3%

b. NAPL breakthrough was observed during the test – Large amount of NAPL was extracted.

2. SOLV-IT® using two (2.0) pore volumes of 100% commercially available Biosolvent #2

a. TPH recovery percent = 93.4%

b. The NAPL has been mobilized and entire sand column was visually cleaned

c. NAPL breakthrough during the test – Large amount of NAPL was extracted

3. SOLV-IT® using two (2.0) pore volumes of 100% EFC-BTM

a. TPH recovery percent = 94.1%

b. The NAPL has been mobilized and entire sand column was visually cleaned

c. NAPL breakthrough during the test – Large amount of NAPL was extracted

These results are graphically represented below:

The best and the second best recovery results have been achieved by SOLV-IT® utilizing the specially formulated cosolvent EFC-BTM (Test 3), and commercially available biosolvent (Test 2) - 94.1% and 93.4% TPH removal, respectively. A drawback of these approaches is poor cost effectiveness; although these approaches have achieved excellent NAPL recovery, large volumes (two pore volumes) of the pure cosolvents must have been utilized. The cost of such SOLV-IT® events can reach at least three (3) times more than SURFAC®/SOLV-IT® demonstrated on Test 1 and 2. The third best approach has been achieved by SURFAC®/SOLV-IT® (Test 1 – 90.3% recovery); it utilized only half (0.5) pore volume of pure commercially available cosolvent (Biosolvent #2) followed by one (1.0) pore volume of dilute formulated surfactant solution (EFSTM – 4.0%). Because the cost of the dilute surfactant (EFSTM) is at least 10 times cheaper by volume compared to pure cosolvents, Test 3 would be far more cost-effective compared to Test 4 and 10. 90.3% NAPL recovery achieved during Test 3 is merely 3.8% less than the best approach as seen on Test 10. SURFAC®/SOLV-IT® may achieve as good as SOLV-IT®; whereas, the cost-effectiveness could be at least three times better than SOLV-IT®.

Recommendations

At this stage of EcoVac’s Coal Tar remediation research, we identified the best cosolvent (EFC-BTM) for remediation of viscous coal tar; however, EFC-BTM has not been tested with SURFAC®/SOLV-IT®. We will combine the surfactant (EFSTM) and EFC-BTM for the subsequent testing (Test 11). Additionally, we will test other types of formulated surfactants to compare the recovery effectiveness.